- Design of industrial equipments -

Definition of customer's needs

Our industrial engineering experts can produce detailed analysis of customer's needs, in order to ensure everything is being considered, but also that nothing will be done needlessly. Our payback analysis can lead to the determination of which parts of one solution is most profitable, which could be left aside, or even what could be done in order to maximize the investment; all of which is in the client's interest. The aim of Cosinus intervention is the integration of equipment, labour and material, in order to establish processes that optimize productivity and product quality, as well as the business's global growth and profitability.

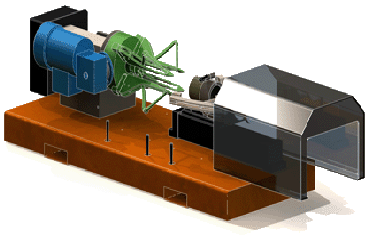

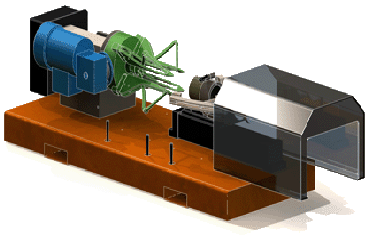

High voltage test machine

Automatic system, compact and sedentary, conceived to carry out tests with tensions of more than 1 500 V.

Cosinus conceives and develops, according to your requirements, industrial equipment adapted to your needs. Our unique approach gives you the opportunity of "pre-visualizing" all your new equipment in their context of use, in order to manage floor space in an optimal way, but also to detect possible interferences or to offer new design possibilities. Our development process is centered on a close cooperation with the customer, which increases the possibilities of innovation and considerably reduces the associated development costs.

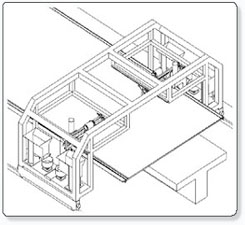

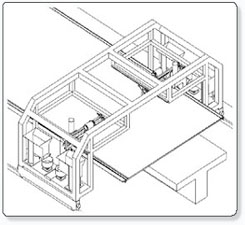

18 L H2O bottles handling concept line

Concept line allowing the paletisation of 900 bottles per hour

This grinding station allows fast changing of the type of parts to be proceeded, thanks to the unique interchangeable revolving table system

Automatic loading of the appropriate program according to what fixture is being used

Ergonomic table allowing the assembly of 750 insulators per day

Conceived in order to meet a not very common need, this machinethreads an insulating rubber sheath around an electric connector. The positioner of sheath draws aside rubber, covers surface to be insulated and folds up the rubber sheath into two.

Capacity of accumulation being able to reach 393ft at a speed of 197ft/min.

Range of equipment being able to adapt to the most restricted environments.

Bidirectional pneumatic grip

Having a gripping force of 132 lb, this grip is used to handle U shaped stems supporting 33 lb of material.

Automated machine allowing to insert 8 studs per minute with a push of 6 tons.

The bracket mounted system of compensation eliminates all the physical efforts from the operator